A neutron source facility in Sweden seeks to bring European materials research and green innovation to unmatched levels

On the beautiful outskirts of Lund, one of the largest research infrastructure projects in Europe, the European Spallation Source (ESS), is being built. Owned by 13 European countries, the ESS will be the home for the world’s most powerful neutron source. By receiving researchers from all over the world, the facility aims to pave the way for pioneering scientific breakthroughs and to answer humanity’s biggest questions—by going small, examining materials on a nanoscale level using subatomic particles.

“There are many fields vital for all of us that the ESS will affect,” says Pia Kinhult, ESS head of host state relations. “We are part of the chain that seeks to push innovation in Europe and find solutions to climate change and other societal challenges.”

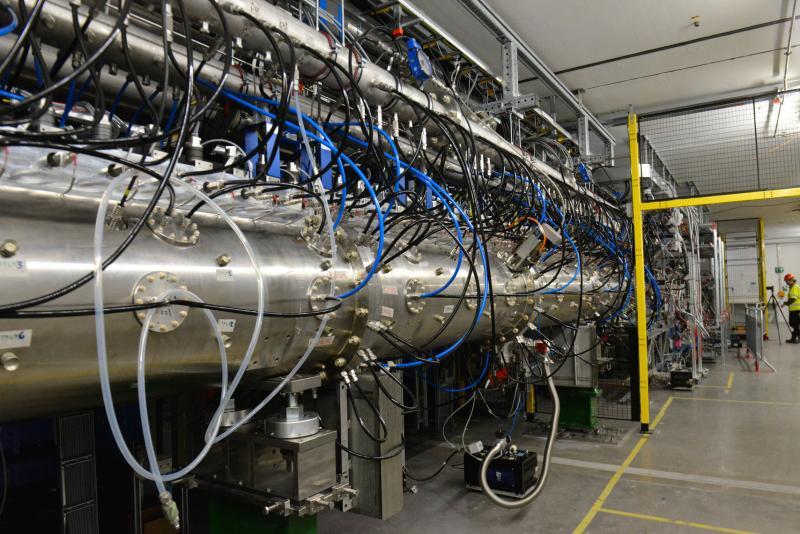

But building a 700-meter facility (the size of 13 football pitches) equipped with 15 state-of-the-art instrument and support laboratories, as well as a 600-metre-long proton accelerator, is a major investment. The European Investment Bank is backing ESS with a credit facility to ensure that Europe stays at the forefront of international scientific research.

ESS’ experiments will provide scientists with a unique insight to better understand and develop the materials of the future for a wide variety of fields, from energy to life science

Faster and smarter neutron experiments in Sweden

Don’t let their microscopic size fool you, neutrons are powerful tools for making sense of the world around us. These particles found in the nucleus of an atom have significant benefits over other technologies for the study of all kinds of matter and materials.

“Neutrons are fast, smart, and ‘nice’, as they do not destroy the samples like, for example, x-rays,” says Kinhult. “They enable the study of fragile samples, like proteins and living cells, and also the detection of hydrogen, which plays a crucial role in almost all biological processes.”

Spallation is the process of producing neutron beams by hitting a tungsten target with protons accelerated to almost the speed of light. By observing the released neutrons passing through materials, the researchers can understand how atoms and molecules in the samples interact and behave, which in turn helps to improve and create new materials.

“ESS can be compared to a giant microscope,” says Julia Öberg, press officer and one of 500 employees at ESS. “Our experiments will provide scientists with a unique insight to better understand and develop the materials of the future for a wide variety of fields, from energy to life science.”

European support for innovation in Sweden

In 1932, James Chadwick proved the existence of the neutron from the convenience of a relatively small laboratory in England. However, experiments using neutrons today require larger facilities and more sophisticated instruments.

ESS is a huge endeavour that took many years to come together, with civil construction due to finish in December 2021. “Historically, the construction of such facilities has not been easy,” says Kinhult. “We realised early on that we would need to secure liquidity for both construction and to support our operational capabilities, which will continue in the next years.”

The European Investment Bank’s €50 million financing for ESS is backed by InnovFin–EU Finance for Innovators, an initiative launched by the EIB Group in cooperation with the European Commission under Horizon 2020, the EU research and innovation programme. The credit facility is the third instalment since 2016, for a total of €200million.

“InnovFin provides financing in support of research and innovation projects, such as research infrastructures,” says Aristomenis Pofantis, lead engineer for sustainable and digital industries at the European Investment Bank. “With this line of credit, the EIB wanted to make sure that this highly ambitious project can be completed without costly delays, despite the ongoing difficulties caused by the COVID-19 pandemic.”

With the EIB’s help, the ESS can continue construction and initial operations without disruptions. “The EIB helps us to drive our project forward and bridge the project costs with the contributions from the ESS member states,” says Öberg. “It is good to have the support and strong commitment from EIB in bringing this large-scale research infrastructure to completion.”

Every year, the facility will welcome up to 3 000 visiting researchers from universities, institutes and companies around the world who will carry out about 800 experiments

Greener research and innovation in Europe

Europe has always been at the forefront of neutron research, but ESS is much more than just a neutron source.

Once finished, the research infrastructure will reshape the way we perceive research in Europe and the rest of the world. “It is a huge technological step that will take materials research to unmatched levels and generate up to 100 times more neutrons to the instruments than similar facilities,” says Öberg. “It will strengthen and consolidate the flagship role of European research within neutron scattering.”

Every year, the facility will welcome up to 3 000 visiting researchers from universities, institutes and companies around the world who will carry out about 800 experiments.

“Collaboration is at the core of ESS,” says Kinhult. “We will have a broad range of instruments that researchers can use to make experiments and obtain higher quality research data necessary to find solutions to modern problems.”

The research facility has a green dimension, enabling unique research possibilities within sustainability and climate, as well as heating thousands of homes and other properties in surrounding areas with its surplus energy.

“Today, everything is based on research data, including the fight against climate change,” says Kinhult. “With the experiments at our facility, we will contribute to the development of innovative and more sustainable materials and more environmentally friendly energy and transport solutions.”